Transformers

Introduction

Transformers are electrical static devices (no moving parts) which are capable of transferring alternating electrical power from one circuit or system to another at the same frequency through a magnetic field (induction). A conventional single-phase transformer has a primary and a secondary winding separated by a common iron core as shown below.

The primary winding is connected to the source and the secondary winding is connected to the load. The primary winding acts as an electromagnet which produces flux in the core. Consequentially, the secondary winding acts as a generator, producing a voltage from that flux, which is proportional to the turns ratio between the two windings. Notice there is no physical connection between the two systems (other than grounding and bonding). Because of the absence of any physical connection between the secondary winding and the original power source (or service) in the primary winding, the NEC (National Electrical Code - NFPA70) refers to transformers as a “separately derived system.”

Separately Derived System - A premises wiring system whose power is derived from a source of electric energy or equipment other than a service (Article 100 Definitions).

Exception: Auto-Transformers only have one single winding and are NOT considered a separately derived system since the primary and secondary windings are NOT separated by a magnetic field but share connections to a common winding.

Operation

Based on the turns ratio in each winding, a transformer performs the following functions:

Step Down - Primary has more turns in its windings than the the secondary.

Step Up - Secondary has more turns in its wings than the primary.

Isolation - Same number of turns in each winding. Therefore, there is no step-up or step-down…only “isolation” (also called “decoupling”).

The greater the number of turns in the winding, the greater the voltage drop across that winding. Consequently, if the winding voltages are known, the greater voltage goes with the greater winding resistance.

Example:

Npri / Nsec = Vpri / Vsec

480VAC / 240VAC = 2

Therefore, the turns ratio is 2:1.

It should be noted, assuming both the primary and secondary winding conductors have the same cross-sectional area, the winding with the greater voltage always has the greater number of turns. Any transformer can also be wired in the forward or reverse direction to make it a step-up OR step-down transformer. It should also be noted that all transformers are bi-directional. Meaning, either winding can be used as a primary or secondary winding. Therefore, any transformer with windings having a different number of turns can be made into a step-up or step-down transformer simply by connecting the desired winding to the source and the other winding to the load.

3-Phase Transformers

A three-phase transformer is merely three single-phase transformers in a single package. In fact, you can easily make a three-phase transformer from three individual single-phase transformers by wiring them in a three-phase configuration. Three 1KVA transformers wired in Delta-Wye, 3-phase is a 3KVA transformer bank. Two advantages is, often smaller size and able to run two banks if one fails. One disadvantage is, higher cost.

3-Phase Transformer Configurations

The primary and secondary windings of 3-phase transformers can be connected in different configurations to meet just about any voltage requirement as follows:

NOTE: When the winding configuration is different (i.e. Delta-Wye or Wye-Delta), there is a 30-degree phase shift (also called angular displacement).

Delta-Wye: Angular displacement 30-deg. Most common worldwide. Provides a 3-phase 4-wire service with a bonded neutral. Also used in step-up transformers in long-distance power distribution networks.

Delta-Delta: Angular displacement 0-deg. Suitable for both ungrounded and effectively grounded sources. Used for short runs in high-power distribution networks, and where high motor starting torques are required. Another advantage of this type of connection is that even if one transformer winding is disabled, the system can still continue to operate in open delta at reduced KVA capacity.

Wye-Delta: Angular displacement 30-deg. Used in step-down transformers at the sub-station end of the in-coming high-voltage transmission lines.

Wye-Wye: Angular displacement 0-deg. Suitable for both ungrounded and effectively grounded sources. This connection is incapable of furnishing a stabilized neutral and its use may result in phase-to-neutral overvoltage (neutral shift) as a result of unbalanced phase-to-neutral load. Suitable for a three-wire service only, even if the secondary neutral is grounded. Used in small high-voltage transformers. Line voltages on both sides must be in phase with each other and the connected load must be balanced.

Transformer KVA Rating - Sizing Based on Voltage and Amp-Load

All transformers are rated in KVA since they are primarily inductive and thus, are characterized by inductive reactance. The formulas to calculate KVA are as follows:

For Single-Phase Transformers:

KVA = (E x I) / 1000

For 3-phase Transformers:

3-phase transformer is:

KVA = (E x I x SQRT 3) / 1000

Where:

E = AC Voltage, I = AC Current, SQRT 3 = 1.732

Calculating Line Currents

For Single-Phase Transformers:

Amps = VA / E

For 3-Phase Transformers:

Amps = VA / (E x 1.732)

Calculating OCPD (Over-Current Protection Device)

NOTE: These OCPD’s are to protect the transformer, NOT the conductors. Therefore, the OCPD’s and conductors should always be sized based on full KVA rating at 100% continuous loading. These calculations are based on NEC 450.3(B), Note 1, 240.6(A), and Table 310.16(B), 60-Deg C column (terminal rating).

Apply the following formulas for Primary and Secondary OCPD calculations.

For Single-Phase Transformers:

Amps = VA / E

For 3-Phase Transformers:

Amps = VA / (E x 1.732)

Calculating Conductor Sizes

At a minimum, match the amp-value of the OCPD using Table 310.16 (B), 60-Deg-C column for 100 amps or less, and the 75-Deg-C column for greater than 100 amps, unless the lugs are marked otherwise.

Grounding and Bonding

This section applies to BOTH single-phase and 3-phase transformers.

Since the NEC recognizes all transformers as “separately derived systems,” the secondary must have a grounded neutral based on the area of the ungrounded line conductors and a system bonding jumper must be installed in the same location where the grounding electrode conductor terminates to the neutral point of the transformer. REF: Articles 250.102(C), 250.30 (A)(1), 250.28 (D)(1), 250.30 (A)(4), 250.30 (A)(5), and Article 100.

NOTE: According to the NEC, the grounding jumper here is treated as a grounding conductor for a separately derived system, NOT as an equipment grounding conductor. Therefore, this grounding conductor CANNOT be downsized as such.

Frequency Considerations

The frequency of an AC waveform is NOT in any way altered by a transformer. However, careful consideration must be taken on the design frequency of the transformer core before applying any voltage to it. Lower frequency voltages produce a greater amount of flux since they are producing back-EMF for longer periods of time.

For example, a 60Hz transformer can only be used on a 60Hz system. However, a 50Hz transformer can be used on both a 50Hz and a 60Hz system, since its core is about 30% larger and can handle the greater amount of flux. If you connect a 60Hz transformer (which has a smaller core) to a 50Hz voltage, the flux density in the core will be 20% greater than its 60Hz design basis (i.e. 60Hz / 50Hz = 1.2) and it will cause flux saturation and overheating of the core. In other words, the smaller core cannot handle the greater amount of flux. This goes for both single-phase AND 3-phase transformers.

Conclusion

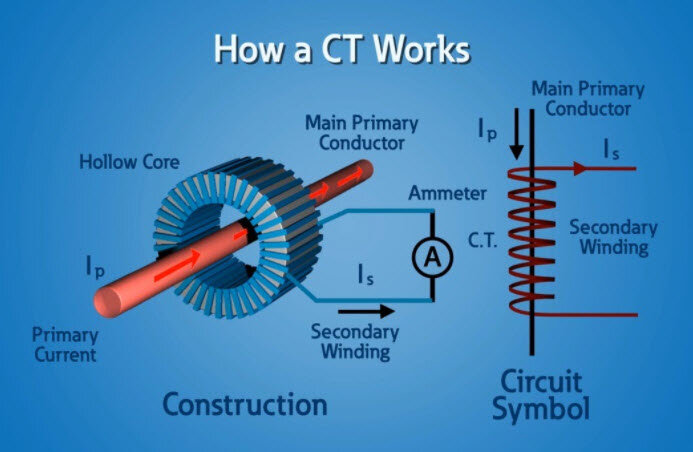

For more information on transformer applications and theory, check for other posts on the Electrician’s Journal site. There are several other transformer types, such as CT’s (Current Transformers), PT’s (Potential Transformers), Auto-Transformers, Buck-Boost Transformers, Parallel Transformers, and advanced 3-Phase Transformer applications for power distribution networks. Check out our additional posts on these other transformer types. Enjoy!